| fep lc215 technical parameter: | |||

| physical performance | specific gravity | g/cm3 | 2.12-2.17 |

| melting flow rate | g/10min | 15 | |

| melting point | ℃ | 265±10 | |

| mechanical performance | tensile strength | mpa | ≧15 |

| breaking extension | % | ≧200 | |

| hardness | shore hardness | 56 | |

| yield strength | mpa | - | |

| coefficient of dynamic friction | —— | 0.3 | |

| thermal performance | maximal temperature of continuous work | ℃ | 200 |

| thermal distortion temperature | ℃( 1.82mpa) | 47 | |

| coefficient of linear expansion | (-10-5/℃) | 8-15 | |

| electrical performance | volume resistanc | ω.cm | >1018 |

| insulation breakdown voltage | kv(3.2mm thickness) | 20 | |

| relative dielectric constant | 1khz | 2.1 | |

| dielectric loss angle tangent value | 1khz | <0.0005 | |

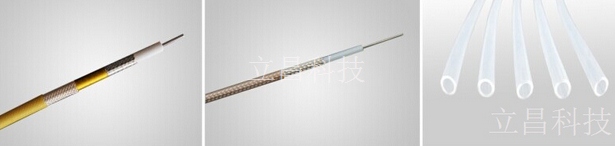

| application fields | electron wire, rf coaxial wire, carbon fiber hot wire | ||

| extrusion application | 30awg-14awg wire, wall thickness below 0.5mm, od1.0-3.0 compound wire protective jacket (like rf wire) | ||